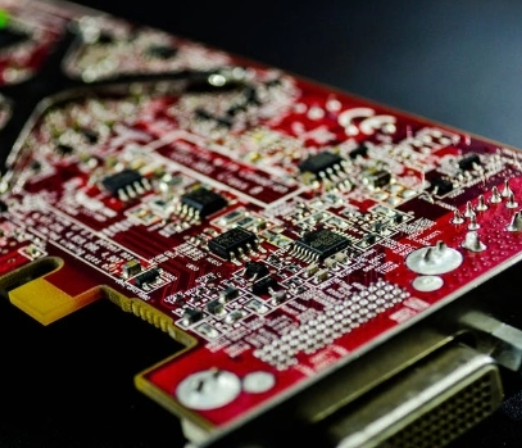

Building products with the highest quality components reduces operational expenses, maintenance, and returns while building customer confidence. Aegis Components, Inc. is dedicated to providing products and services of the highest quality, performance, and reliability. To achieve this goal, we have developed a systematic quality management process that supports our stringent quality standards throughout every stage of a transaction.

We understand that in order to earn your long-term business, we must diligently and consistently maintain our quality standards. Our comprehensive approach combines our years of experience with unbiased and objective inspection services from world renowned test facilities at no additional cost to our clients. This allows us to provide the finest and most detailed quality control process, and tailor our processes to your unique requirements.

At each step between sourcing and delivery, quality is always our foremost priority.

Our AVL has undergone decades of scrutiny and refinement. The suppliers we work with share our mission to deliver the highest quality products and service.

When we initially receive your parts, all data is recorded and photographed for traceability and easy reference.

Our team inspects all aspects of the products including packaging, labels and barcodes, markings, and dimensions to identify substandard components.

To enhance operating efficiencies and optimize risk mitigation, we provide access to best-in-class third party test partners for inspection and testing services.

Our team performs a final inspection of your order and inspects to ensure that your product is optimally protected during transportation.

Once the authenticity of the parts has been confirmed and your order has been safely packaged, we will ship your order to you in the quickest and most cost-effective manner.

To enhance operating efficiencies and optimize risk mitigation, we provide access to best-in-class third-party test partners for inspection and testing services. By leveraging the core competencies of these proven partners, we offer unbiased and objective component authenticity analysis.

This model allows us to direct more of our resources toward solving our customer’s supply chain issues and driving consistent value; while maintaining unparalleled inspection and test services.